Why Deep Drawn Custom Sheet Metal Stainless Steel Punching Deep Drawing Parts are the preferred solution for many industries?

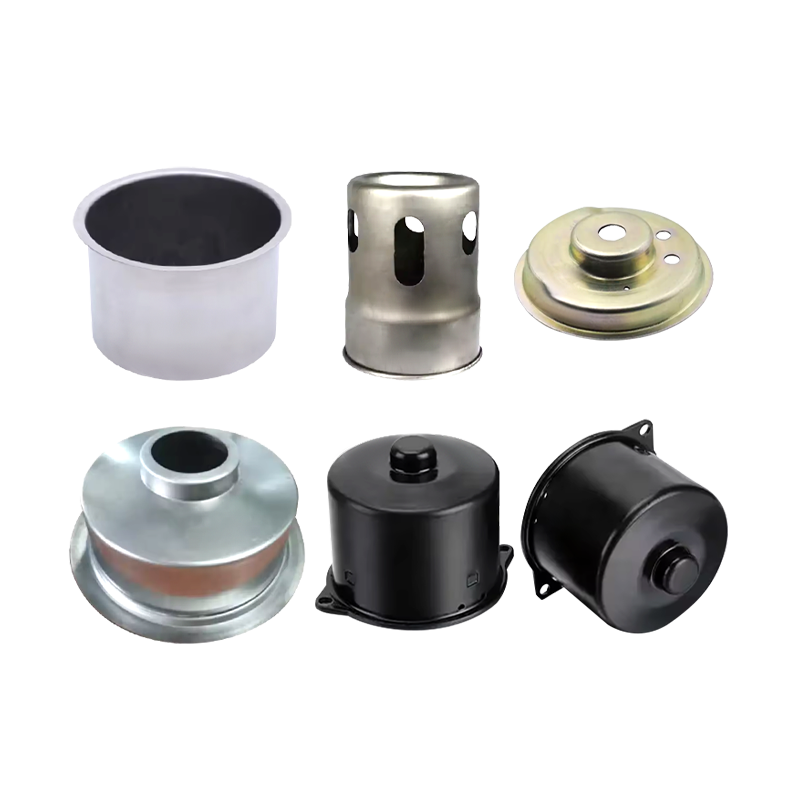

Ningbo Dasheng Metal Products Co., Ltd. is a company specializing in metal stamping, deep drawing and welding, serving a wide range of industries. It excels in the production of deep drawn custom sheet metal stainless steel punching deep drawing parts. Stainless steel is chosen as the preferred material because of its good corrosion resistance, high strength and excellent machinability. Throughout the manufacturing process, including key steps such as material selection, stamping, deep drawing, cutting and surface treatment, we use precision mold design and state-of-the-art processing equipment to ensure the highest precision and quality of components.

The stamping process is one of the core steps in manufacturing these parts. It uses strong pressure to punch the stainless steel sheet into the desired shape. Subsequently, the deep drawing process further stretches and shapes the material to form more complex structures. The cutting process is used to remove excess material and ensure the dimensional accuracy of the parts. Finally, the surface treatment not only improves the appearance quality of the parts, but also enhances its corrosion resistance and wear resistance.

Stainless steel plays a vital role in the manufacture of Deep Drawn Custom Sheet Metal Stainless Steel Punching Deep Drawing Parts. Its main advantages include:

Good corrosion resistance: Stainless steel can maintain stable performance in a variety of harsh environments and is not easy to rust or corrode, which is especially important for parts that need to be used for a long time.

High strength and toughness: Stainless steel has high strength and toughness, can withstand greater mechanical stress and impact, and ensure the reliability and durability of parts.

Good machinability: Stainless steel is easy to process and form through processes such as stamping and deep drawing to meet the requirements of complex shapes and precise dimensions.

Surface treatment is an important means to enhance the performance and appearance of Deep Drawn Custom Sheet Metal Stainless Steel Punching Deep Drawing Parts. Different surface treatment methods have different effects: By plating a layer of corrosion-resistant metal on the surface of stainless steel, its corrosion resistance can be further enhanced and its gloss and color can be changed. Spraying can provide a wide range of color and texture options, which can simulate almost any appearance effect while enhancing the wear resistance and corrosion resistance of the parts. These surface treatment methods not only improve the practical performance of the parts, but also enrich their visual performance, making them more in line with market demand.

Deep Drawn Custom Sheet Metal Stainless Steel Punching Deep Drawing Parts are widely used in many fields due to their good performance advantages. They are used to manufacture key components such as automotive engine parts and body structural parts to ensure the safety and reliability of automobiles. Due to their high hygiene standards and corrosion resistance, stainless steel parts occupy an important position in the manufacture of medical equipment. Food contact parts require materials that are non-toxic, corrosion-resistant and easy to clean. Stainless steel is the ideal choice to meet these requirements. In the chemical industry, stainless steel parts can resist the erosion of chemical media and ensure the stability and safety of the production process.

English

English 中文简体

中文简体 Español

Español