Metal stamping, bending and deep drawing: How can sheet metal processing technology be optimized for greater efficiency and precision?

Sheet metal processing, as the shining pearl of the manufacturing industry, skillfully transforms flat metal plates into exquisite three-dimensional forms and components. Its wide range of technologies and deep applications are remarkable. In this field, metal stamping, bending parts and deep drawing technologies are like three pillars, jointly supporting the pursuit of high-precision, cost-effective and durable products in various industries. Ningbo Dasheng Metal Products Co., Ltd. focuses on providing good metal stamping, deep drawing and welding services for many industries, and is committed to the precise manufacturing of parts and components. It is composed of experienced experts who will work hand in hand with you to deeply understand your needs and ensure that every product can accurately meet your expectations. From carefully selecting materials, to designing efficient molds and tools, to finally creating good precision parts, we have unparalleled expertise and technical strength. Ningbo Dasheng Metal Products Co., Ltd. Whether it is the streamlined beauty of automotive body panels, the precise structure of electronic housings, or the durability and reliability of home appliance parts. To ensure the best results, several factors must be carefully controlled during the stamping process. Selecting the right material, such as steel, aluminum, or stainless steel, is critical as it determines the strength, weight, and corrosion resistance of the part. The design of the stamping die must be precise, taking into account the material's thickness, yield strength, and formability. In addition, the stamping speed, pressure, and lubrication conditions must be optimized to minimize defects and maximize productivity.

Bending is another important step in sheet metal processing, where a flat sheet is transformed into a curved or angled shape. This process is often used to create brackets, frames, and other structural components. The accuracy and repeatability of the bending operation are critical to ensure that the final product meets the required specifications.

The success of bending a part depends on several factors, including the material's ductility, thickness, and bend radius. The choice of bending equipment, such as a press brake or CNC bending machine, also plays an important role. These machines can precisely control the bend angle, force, and speed, ensuring that each part is produced to the highest standards.

To prevent cracks or deformation during the bending process, the proper tools and techniques must be used. This includes the use of bend relief devices to reduce stress concentrations at the bend line, and the use of stops or supports to prevent material deformation.

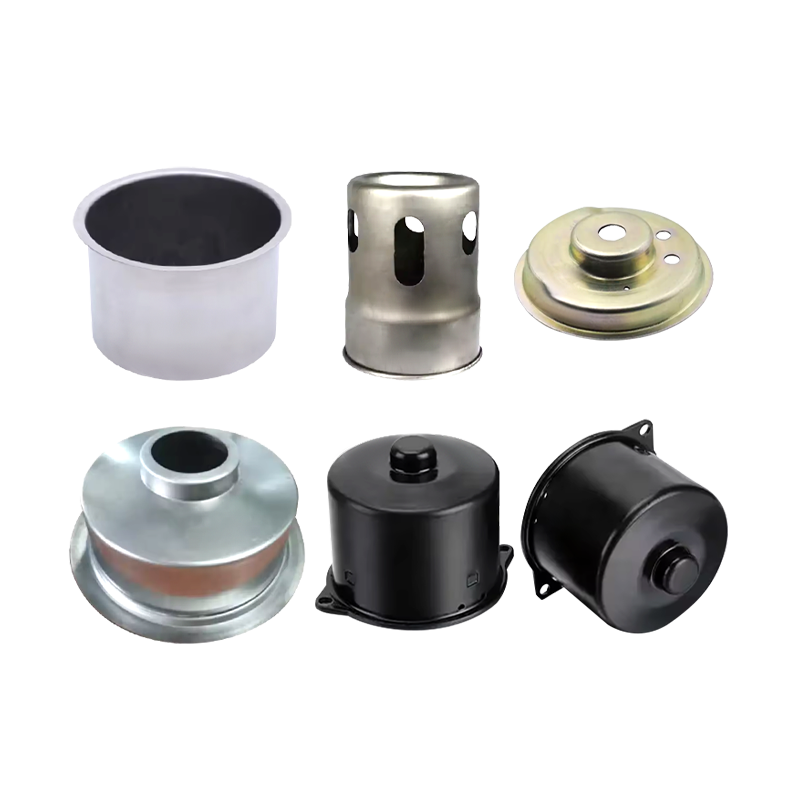

Deep drawing is a special form of sheet metal processing that involves stretching and shaping sheet metal into deep cups, containers or other hollow shapes. The process is extremely challenging due to the large deformations and complex stress patterns involved. However, the resulting parts have excellent structural strength and are widely used in industries such as automotive, aerospace and packaging.

The success of deep drawing depends largely on the formability of the material, which is affected by factors such as grain structure, work hardening and lubrication. The design of the drawing die must be carefully designed to minimize material thinning and wrinkling while ensuring that the part is fully formed without defects.

To optimize the deep drawing process, process parameters must be controlled, including punch speed, draw depth and lubrication conditions. In addition, the use of advanced simulation software can help predict material behavior and detect potential problems before they occur, allowing for more efficient and cost-effective production.

English

English 中文简体

中文简体 Español

Español