How to optimize Sheet Metal Stamping Parts Metal Stamping Fabrication Service Stamping Sheet Metal Cover to meet the needs of high precision and lightweight?

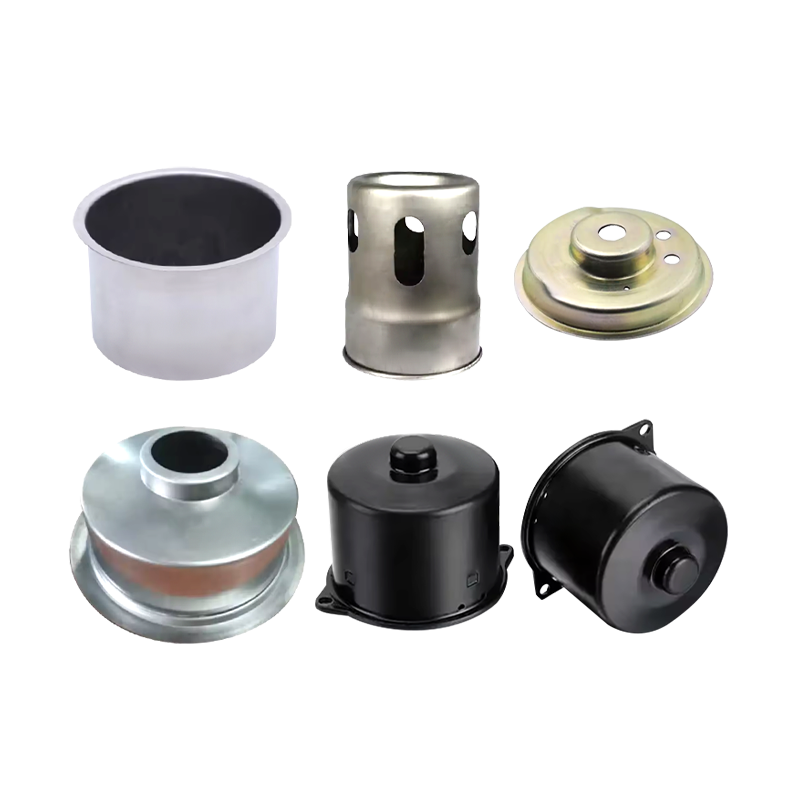

Ningbo Dasheng Metal Products Co., Ltd. specializes in providing comprehensive Sheet Metal Stamping Parts and Metal Stamping Fabrication Services, encompassing the entire process from material preparation to final quality inspection. Our expertise lies in utilizing precision molds to transform metal sheets into intricately shaped and dimensionally accurate parts, catering to a diverse range of industries.

Our skilled team collaborates closely with clients to understand their exact requirements, ensuring that every aspect of the production process – from material selection and effective tooling design to the final precision-manufactured part – meets the highest standards of quality and performance. With a focus on precision, efficiency, and customization, Ningbo Dasheng guarantees that every Sheet Metal Stamping Sheet Metal Cover produced adheres strictly to your specifications and exceeds industry quality benchmarks.

Sheet Metal Stamping Parts Metal Stamping Fabrication Service Stamping Sheet The strength of Metal Cover directly determines its load-bearing capacity and durability. In terms of material selection, high-strength steel such as DP600 can provide excellent strength and rigidity and is suitable for applications that need to withstand large external forces. However, for situations where lightweight requirements are high, lightweight and high-strength materials such as aluminum alloys have become a better choice. These materials can significantly reduce the weight of the product and improve overall performance while maintaining a certain strength.

Corrosion resistance is crucial to the service life of Sheet Metal Stamping Parts Metal Stamping Fabrication Service Stamping Sheet Metal Cover in different environments. Stainless steel is known for its good corrosion resistance and its ability to maintain stable performance in a variety of chemical media. In addition, galvanized steel sheets improve the corrosion resistance of the base material through galvanizing treatment, making it an economical and practical choice. Although aluminum alloy itself has a certain degree of corrosion resistance, it still requires additional protective treatment in specific environments.

Lightweighting is one of the important trends in modern manufacturing. In the production of Sheet Metal Stamping Parts Metal Stamping Fabrication Service Stamping Sheet Metal Cover, choosing less dense materials such as aluminum alloy or magnesium alloy can significantly reduce the weight of the product. This not only helps save energy and reduce transportation costs, but also enhances the market competitiveness of products.

The metal stamping process can achieve high-precision forming processing, ensuring the dimensional accuracy and shape consistency of Sheet Metal Stamping Parts Metal Stamping Fabrication Service Stamping Sheet Metal Cover. The automated stamping production line can significantly improve production efficiency, shorten the production cycle, and reduce production costs. Product specifications and shapes can be quickly adjusted by changing molds to meet the customized needs of different customers. Under mass production, metal stamping manufacturing services can achieve higher material utilization and lower unit costs.

English

English 中文简体

中文简体 Español

Español