Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

Why are metal animal drinking bowls the best choice for safe pet drinking water?

Dec 23,2025 -

What are the common defects and solutions for metal bending parts?

Dec 16,2025 -

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025 -

Precision Deep Drawing & Metal Stamping Solutions | High-Volume Manufacturing Expertise

Dec 01,2025

How does the load distribution from metal pallet feet differ from that of traditional pallet feet made of wood or plastic?

When it comes to pallet design and functionality, the choice of pallet feet plays a crucial role in determining how weight is distributed across the pallet. This distribution is essential not only for the safety and stability of the pallet during storage and transportation but also for ensuring that the pallet can carry heavy loads without compromising its integrity. The load distribution from metal pallet feet differs significantly from that of traditional pallet feet made of wood or plastic, primarily due to differences in material properties, design, and structural capabilities.

One of the main advantages of metal pallet feet is their ability to provide superior load distribution compared to wooden or plastic feet. Metals like steel or aluminum, which are commonly used for these feet, offer higher strength-to-weight ratios than wood or plastic, allowing for more effective weight transfer across the entire structure of the pallet. Metal, being inherently stronger and more rigid than wood or plastic, can handle heavier loads without bending, warping, or breaking. This means that when metal pallet feet are used, the weight is more evenly spread across the entire pallet, reducing the risk of localized stress or damage to the pallet’s base.

In contrast, wooden pallet feet are often subject to wear and tear over time. Wood is more susceptible to cracking, splintering, or breaking under heavy pressure, especially when exposed to moisture or high humidity. These weaknesses in wood can result in uneven weight distribution, which can cause the pallet to become unstable or even collapse under the weight of the load. Additionally, wooden feet may compress or deform under pressure, leading to less reliable load distribution over time.

Plastic pallet feet, while offering more resilience than wood, are generally not as strong as metal. While plastic materials can provide good load-bearing capacity and are resistant to certain environmental factors like moisture, they can deform or crack under heavy or uneven loads. This can lead to instability or an uneven distribution of the load, especially when the pallet is subjected to repeated use or harsh conditions. Plastic pallet feet are often used in lighter applications where the load capacity is not as demanding, but they still cannot match the durability and strength provided by metal pallet feet.

When considering the design and engineering of the pallet feet, metal offers additional advantages in terms of precise engineering and structural integrity. Metal pallet feet can be designed to feature reinforced structures that are able to distribute weight more evenly and prevent pressure points that could lead to failure. For example, metal feet may include features like ribs or cross braces that help spread the load across a broader surface area, ensuring that pressure is not concentrated in one area, which is especially important in high-density stacking or heavy-duty applications.

On the other hand, the load distribution from wooden or plastic pallet feet can be less predictable. The design of wood or plastic feet often lacks the same level of reinforcement, which means that these materials rely more on their natural properties to handle weight. As wood can warp or plastic can crack over time, the load distribution may become increasingly uneven as the pallet is used, affecting the overall performance and safety of the pallet during handling and storage. This is especially true when pallets are stacked or subjected to uneven stress during transport.

Furthermore, the durability and long-term performance of metal pallet feet contribute to their superior load distribution. Unlike wood or plastic, which can degrade or lose strength with exposure to environmental conditions, metal remains robust and resistant to the elements. This is particularly important in industries such as automotive, pharmaceuticals, and food processing, where pallets are exposed to various stresses and environmental conditions. In such applications, the consistency of load distribution provided by metal pallet feet ensures that the goods remain stable and secure, minimizing the risk of damage to products.

Another key factor is the ability of metal pallet feet to handle high-impact or shock loads. When pallets are handled roughly or dropped during transport, the metal feet help to absorb and distribute the shock evenly across the pallet. This can prevent damage to the pallet structure and help maintain an even load distribution, ensuring that the pallet does not fail or collapse under sudden impacts. Wood and plastic, by contrast, are more vulnerable to cracking or breaking when subjected to such impacts, which can disrupt the load distribution and cause instability.

In addition to load-bearing capacity, metal pallet feet offer the advantage of being able to handle extreme weight distribution, particularly in applications that involve very heavy products or dense stacking configurations. Their strength enables them to evenly distribute the weight of multiple pallets stacked on top of each other, maintaining stability and ensuring that the pallets do not become deformed or destabilized. In contrast, wood and plastic pallet feet may buckle under heavy loads, leading to uneven distribution and potential damage to both the pallet and the products it carries.

How do metal pallet feet contribute to reducing maintenance costs in pallet management systems?

How do Metal Pallet Feet enhance the durability of pallets compared to wooden or plastic alternatives?

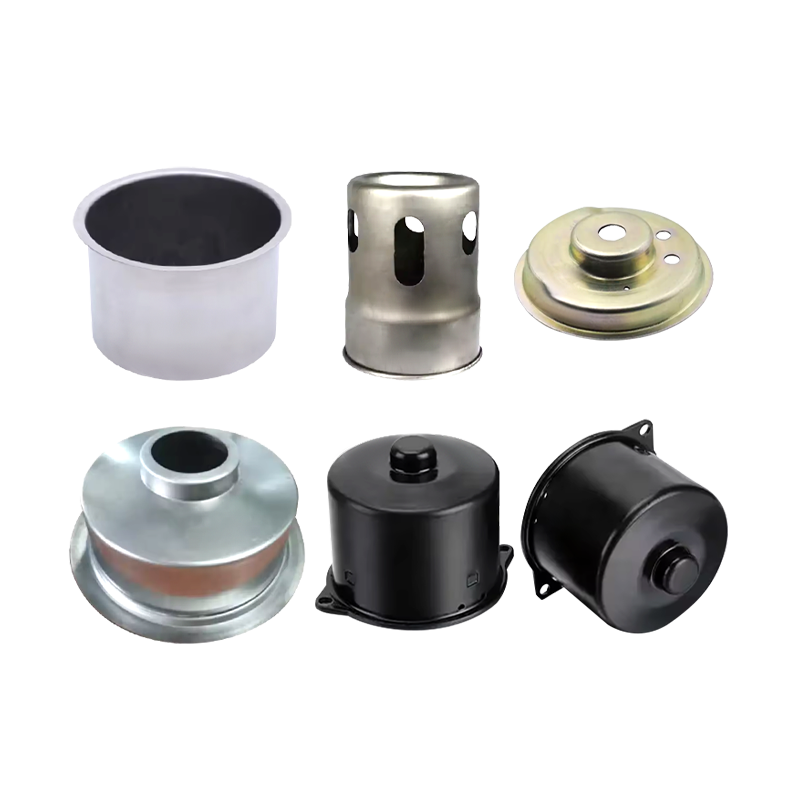

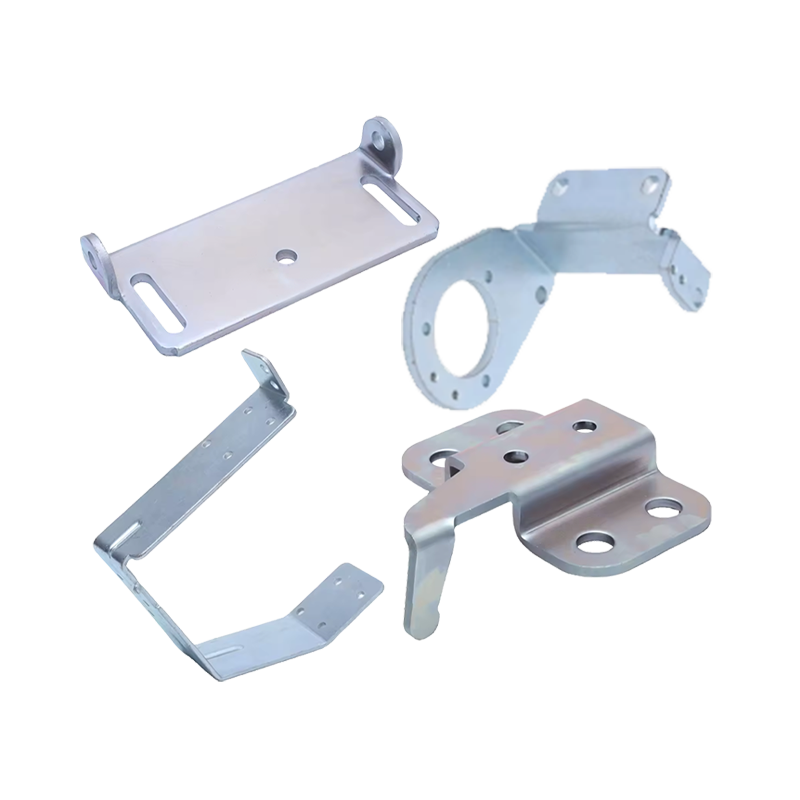

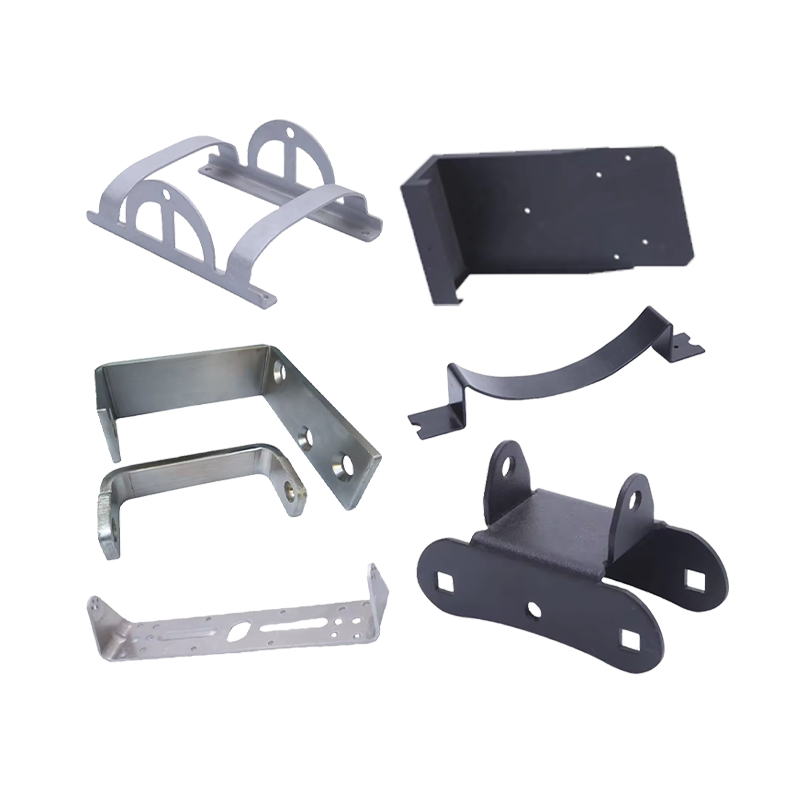

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español