How does metal stamping technology help high-precision component processing?

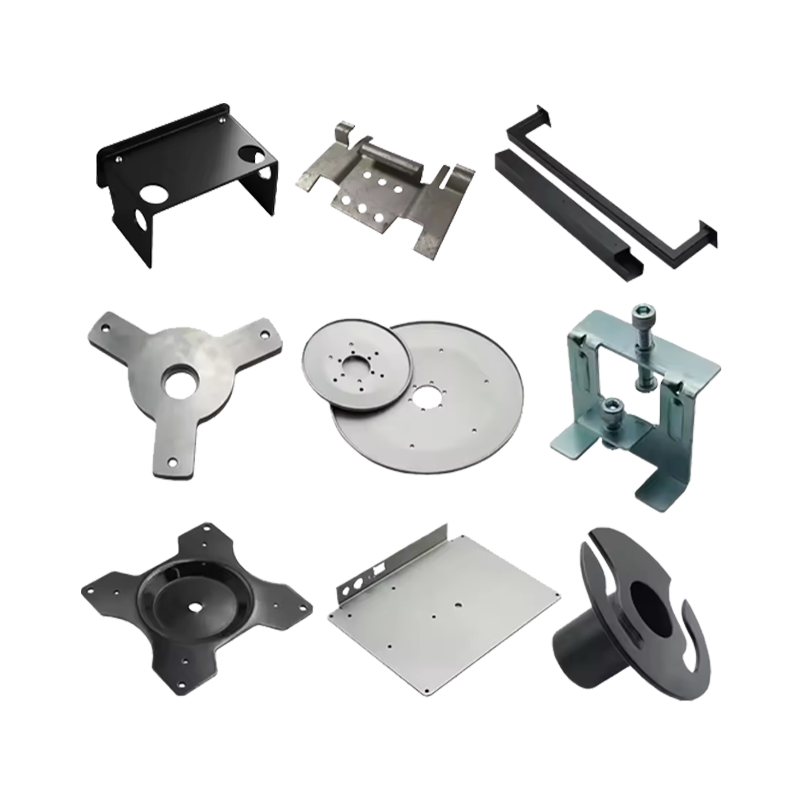

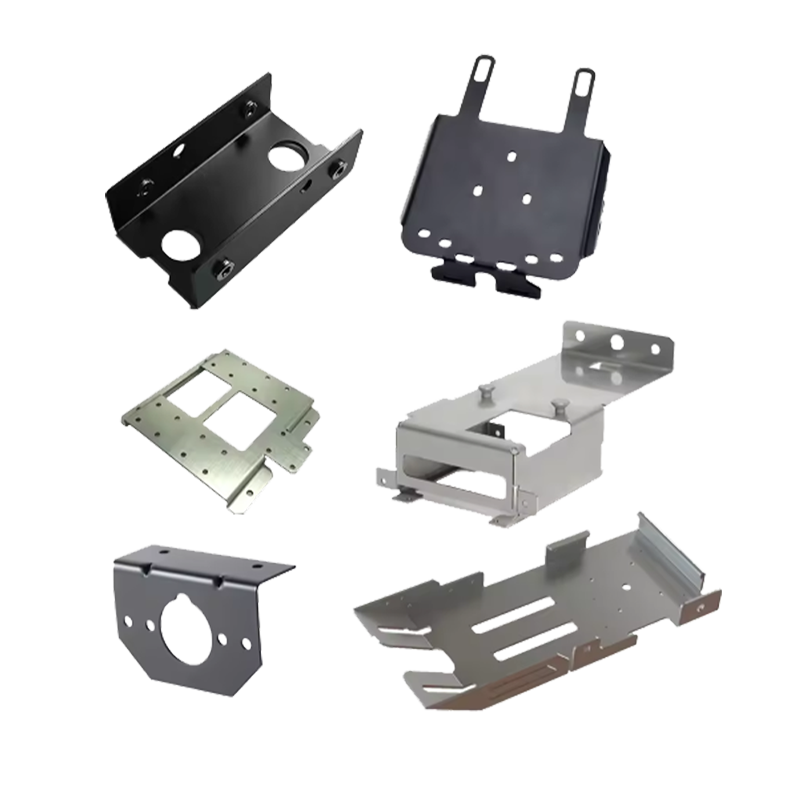

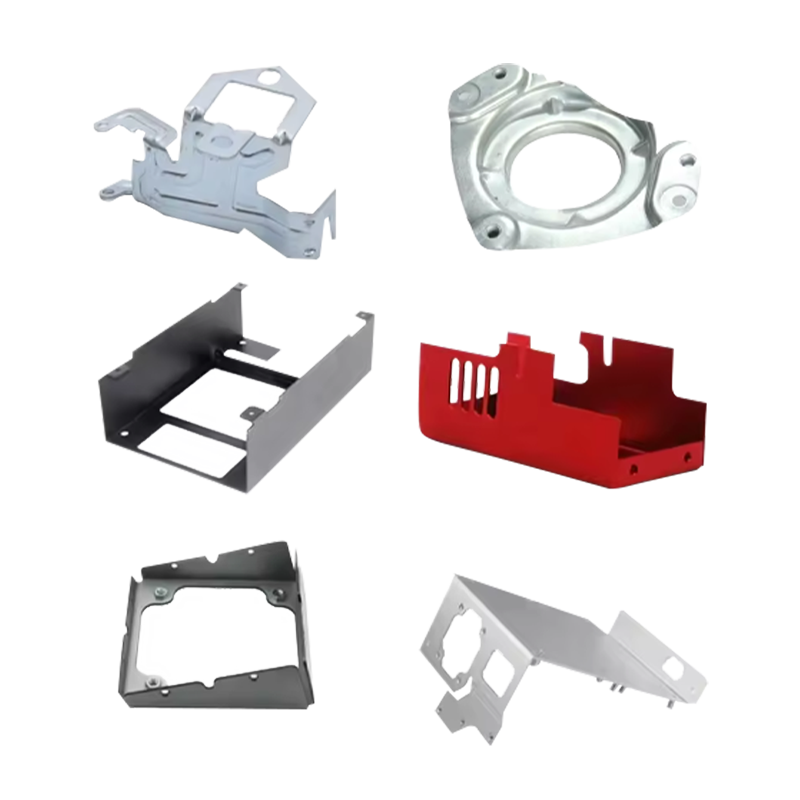

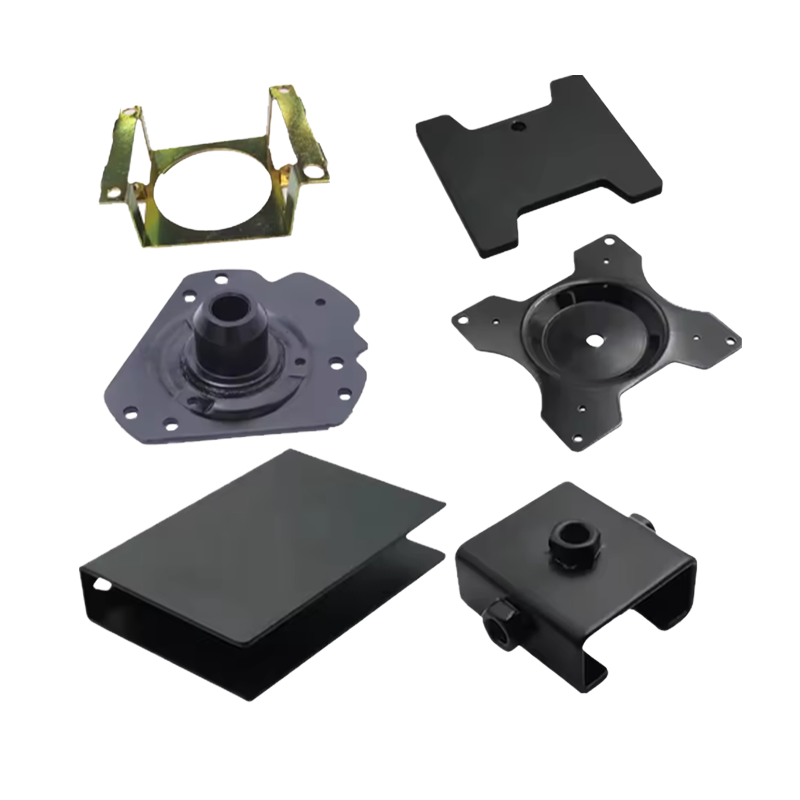

Metal stamping, an advanced manufacturing technology, relies on the precise pressure of the die on the metal sheet to cause it to undergo a plastic transformation, thereby shaping parts that meet the required shape and size. With its good performance, this technology has penetrated into the core production links of many industries such as automobiles, aerospace, electronics, and home appliances. Especially in the manufacturing of large-scale, high-precision parts, metal stamping technology has shown an important position.

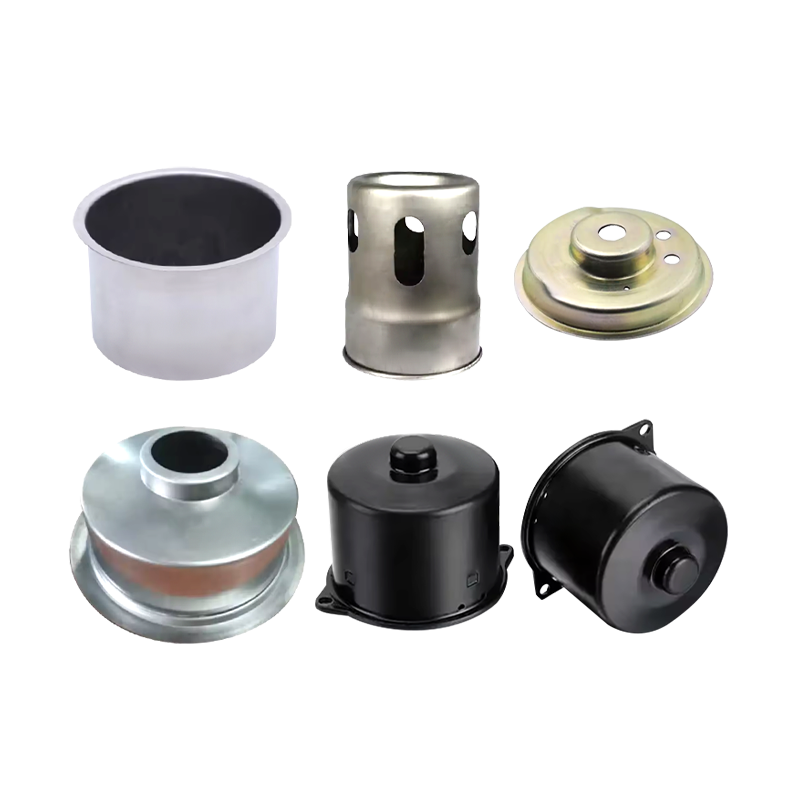

Ningbo Dasheng Metal Products Co., Ltd. is committed to providing customized, high-quality parts solutions for various industries. We have an experienced and skilled team who will work closely with you, from material selection to precision mold design to finished product manufacturing, every step strives to be accurate and correct, ensuring that the final product fully meets your specific needs and high standards of quality requirements.

In High Precision Components Processing, material selection is crucial. Stainless steel, aluminum alloy and titanium alloy have become the most commonly used materials in metal stamping parts due to their unique performance characteristics.

Stainless steel: known for its excellent corrosion resistance and good mechanical properties. Stainless steel stamping parts are not only strong and wear-resistant, but also have good ductility and processability, which are suitable for manufacturing parts of various complex shapes. In addition, the cost of stainless steel is relatively low, which is suitable for large-scale production.

Aluminum alloy: It is favored for its light weight, high strength, good corrosion resistance and easy processing. Aluminum alloy stamping parts are widely used in aerospace, automobile manufacturing and other fields because they can significantly reduce the weight of products while ensuring strength. However, aluminum alloys need to pay attention to temperature control during the stamping process to avoid overheating and cause material performance degradation.

Titanium alloy: It is famous for its high strength, low density, excellent corrosion resistance and heat resistance. Titanium alloy stamping parts are particularly suitable for occasions with extremely high performance requirements, such as engine parts, fasteners, etc. in the aerospace field. However, titanium alloys are difficult to process and costly, and special equipment and processes are required to ensure accuracy and stability.

Stamping processing uses molds for forming, which can ensure the shape and size accuracy of parts and meet the strict requirements of high-precision components. The stamping process has a high degree of automation, which can achieve continuous and large-scale production and significantly improve production efficiency. The material utilization rate of stamping processing is high, which reduces waste and loss; at the same time, the mold has a long life and can be reused, further reducing production costs.

Good surface quality: During the stamping process, the pressure and shear force on the surface of the material make the surface finish and flatness of the parts high, which is conducive to the subsequent surface treatment process.

Although metal stamping technology has many advantages in the processing of high-precision components, its production difficulty and cost control are also issues that cannot be ignored. The difficulty of stamping processing of different materials varies. For example, the processing difficulty and cost of titanium alloy are high, and special equipment and processes are required to ensure accuracy and stability. Therefore, when selecting materials and formulating production processes, it is necessary to comprehensively consider factors such as performance requirements, cost budgets and production conditions.

In order to reduce production costs and improve production efficiency, a series of measures are taken, such as optimizing mold design, improving equipment accuracy, and adopting advanced automation technology. At the same time, strengthening quality control and testing in the production process is also an important means to ensure the quality of high-precision components.

English

English 中文简体

中文简体 Español

Español