Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025 -

Precision Deep Drawing & Metal Stamping Solutions | High-Volume Manufacturing Expertise

Dec 01,2025 -

Which Round Stainless Steel RV Small Cooker Sink With Glass Saves Space? Exploring Space-Efficient Solutions for Mobile Living

Nov 28,2025 -

When Selecting Metal Prts, How to Quickly Match the Mechanical Properties with Actual Application Scenarios?

Nov 21,2025

How does Zinc Coated Steel Deep Drawing Stamping Housing Parts play a good role under different conditions?

The galvanized layer is a key factor in protecting steel from corrosion. The zinc layer is evenly attached to the surface of the steel by electrochemical methods to form a dense protective layer, which effectively isolates the steel from direct contact with corrosive media such as oxygen and moisture. This protective layer can not only resist corrosion in daily environments, but also provide lasting protection under different conditions (such as high humidity and high salinity environments), extending the service life of parts.

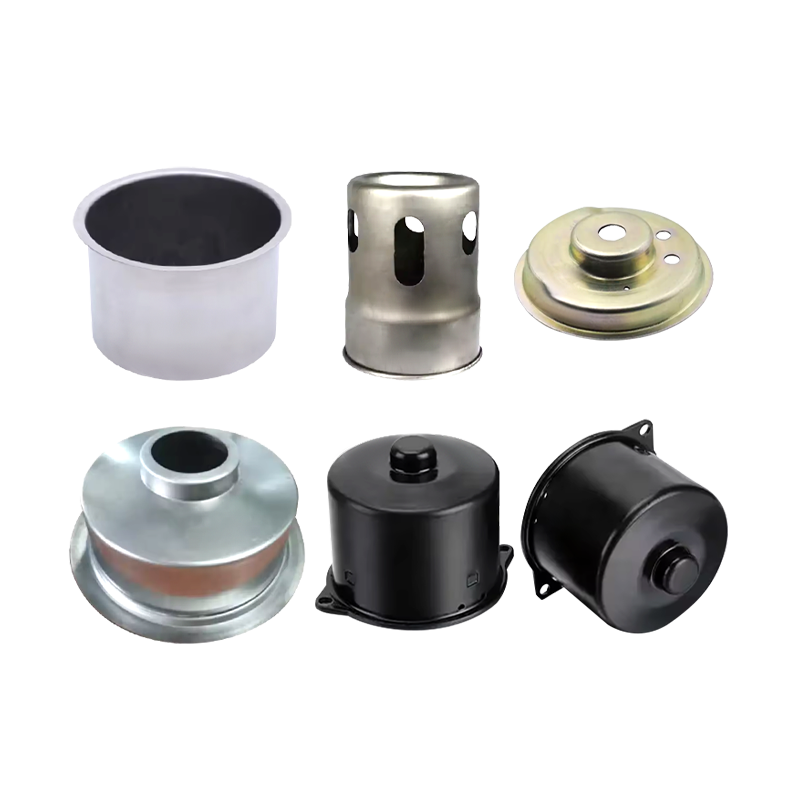

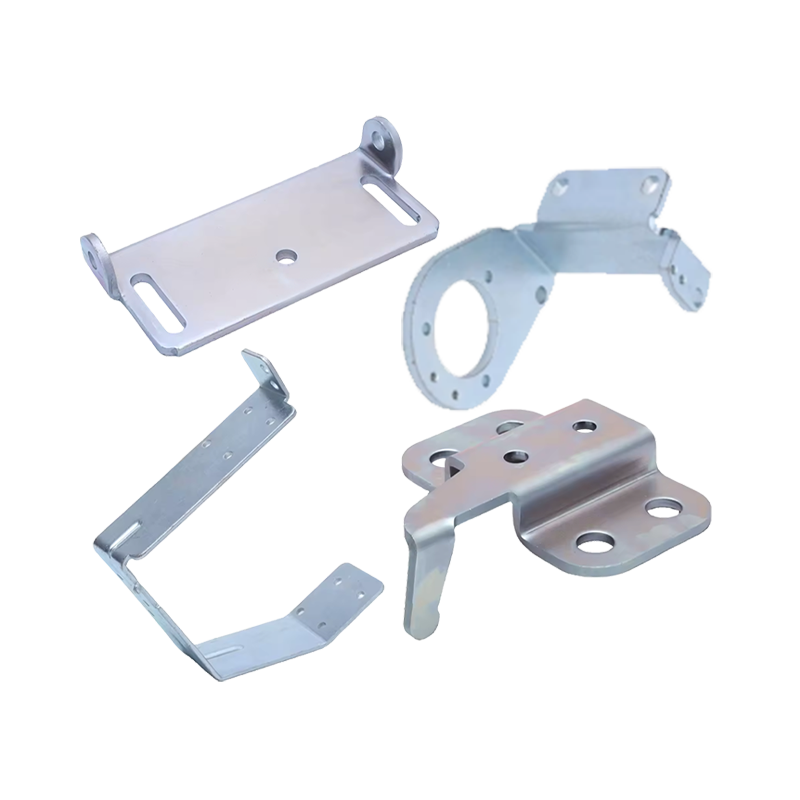

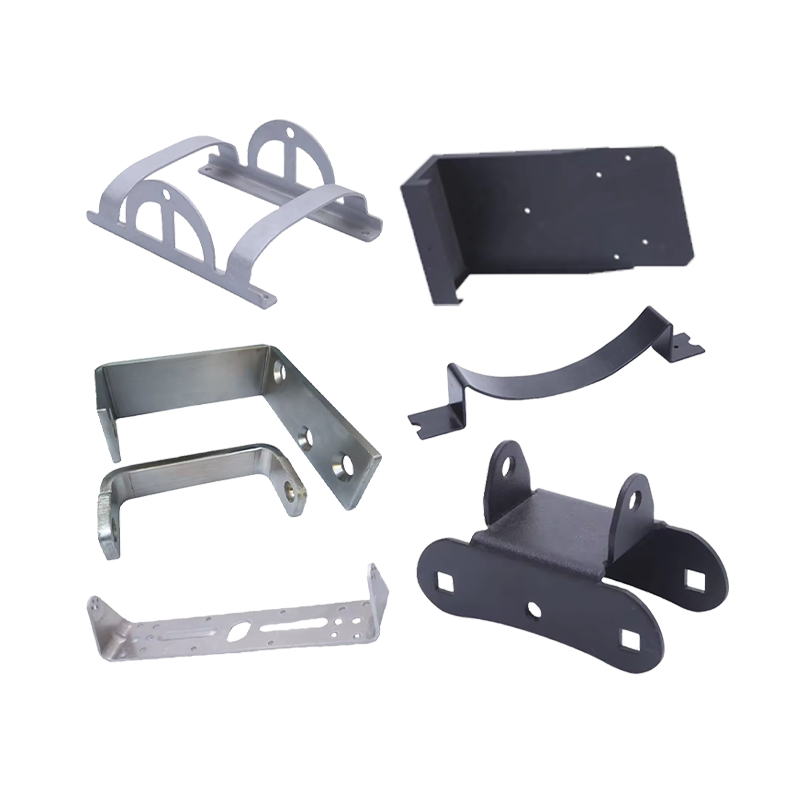

Zinc Coated Steel Deep Drawing Stamping Housing Parts has good plasticity and ductility, and is suitable for complex forming processes such as deep drawing and stamping. This makes it easy to manufacture housing parts of various shapes and sizes from galvanized steel sheets to meet the personalized needs of different industries. At the same time, the deep drawing and stamping process can also improve the precision and surface quality of parts, adding points to the overall quality of the product.

With the popularization of energy-saving and environmental protection concepts, lightweighting has become an important development direction for industries such as automobiles and home appliances. Galvanized steel sheets are relatively light, and the weight can be further reduced by optimizing the design and process. This not only helps reduce the energy consumption and emissions of the product, but also improves the transportation efficiency and market competitiveness of the product.

Zinc Coated Steel Deep Drawing Stamping Housing Parts easily react with oxygen in the air to form a zinc oxide layer in a high temperature environment. Although this provides protection to a certain extent, long-term exposure to high temperatures will cause the galvanized layer to age, lose its luster, and even peel off. This not only affects the appearance quality of the product, but may also reduce its corrosion resistance and service life.

The corrosion resistance of galvanized steel sheets may be severely challenged in different environments (such as marine climates, industrial pollution areas, etc.). Corrosive substances such as salt spray and acid rain in these environments will accelerate the destruction of the galvanized layer and threaten the reliability of parts.

Although galvanized steel sheets have many advantages, their production costs are relatively high. With the increasingly stringent environmental regulations and the improvement of consumers' environmental awareness, how to reduce material costs and reduce environmental pollution has become a problem that the galvanized steel sheet industry must face.

Automobiles are one of the main application areas of Zinc Coated Steel Deep Drawing Stamping Housing Parts. With the rapid development of the automobile industry and the continuous improvement of consumers' requirements for automobile quality, the requirements for corrosion resistance, lightweight and other performance of parts are getting higher and higher. Galvanized steel sheet meets these requirements with its good performance characteristics and has become an indispensable and important material in automobile manufacturing.

Home appliances have high requirements for the corrosion resistance, aesthetics and cost-effectiveness of housing parts. Galvanized steel sheet has become an ideal choice for the home appliance industry with its good formability, corrosion resistance and relatively low cost. Whether it is refrigerators, washing machines or air conditioners, home appliances widely use galvanized steel sheets as housing materials.

With the popularization and improvement of the intelligence of electronic equipment, the requirements for corrosion resistance, electromagnetic shielding and heat dissipation performance of equipment housing are also getting higher and higher. Zinc Coated Steel Deep Drawing Stamping Housing Parts can meet these special needs through the composite use of other materials or the improvement of surface treatment technology, showing broad application prospects in the electronic equipment industry.

High Precision Components Processing Metal Stamping Parts How to balance the needs of process accuracy, material performance and wide application?

What supplies water to the RV sink?

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español