Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025 -

Precision Deep Drawing & Metal Stamping Solutions | High-Volume Manufacturing Expertise

Dec 01,2025 -

Which Round Stainless Steel RV Small Cooker Sink With Glass Saves Space? Exploring Space-Efficient Solutions for Mobile Living

Nov 28,2025 -

When Selecting Metal Prts, How to Quickly Match the Mechanical Properties with Actual Application Scenarios?

Nov 21,2025

High Precision Components Processing Metal Stamping Parts How to balance the needs of process accuracy, material performance and wide application?

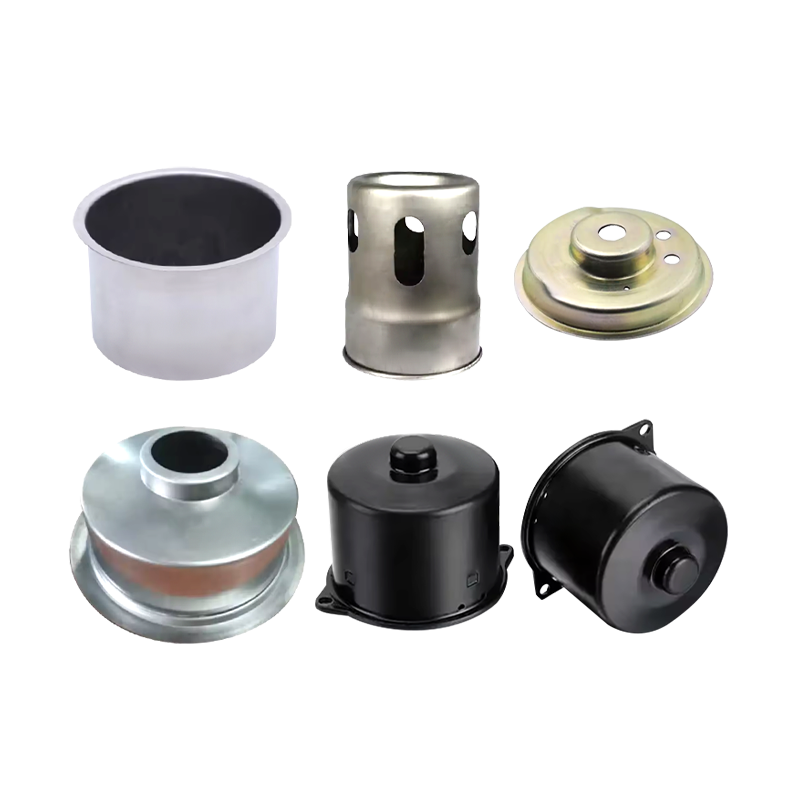

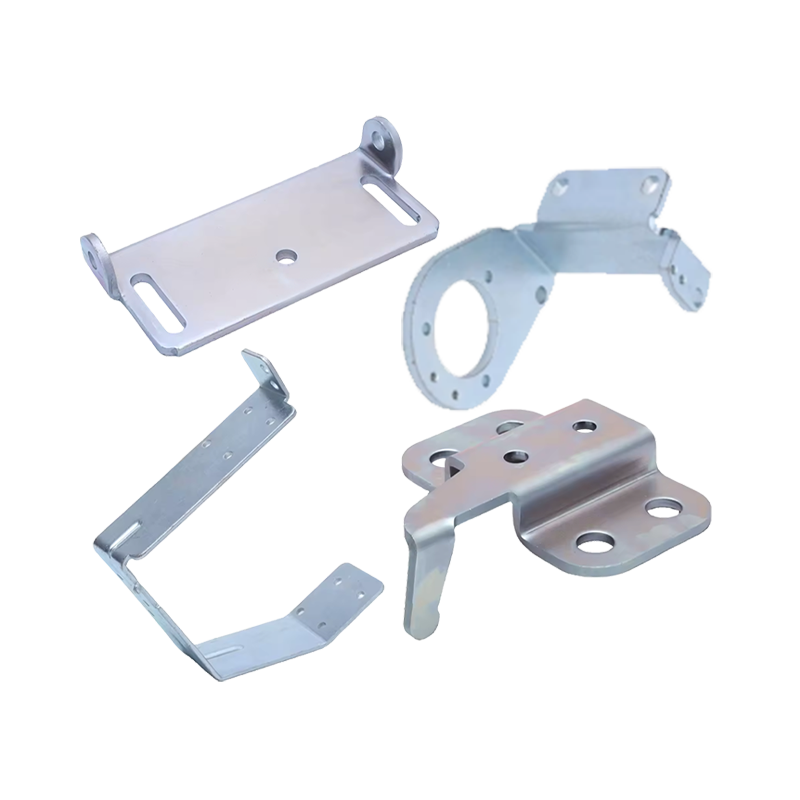

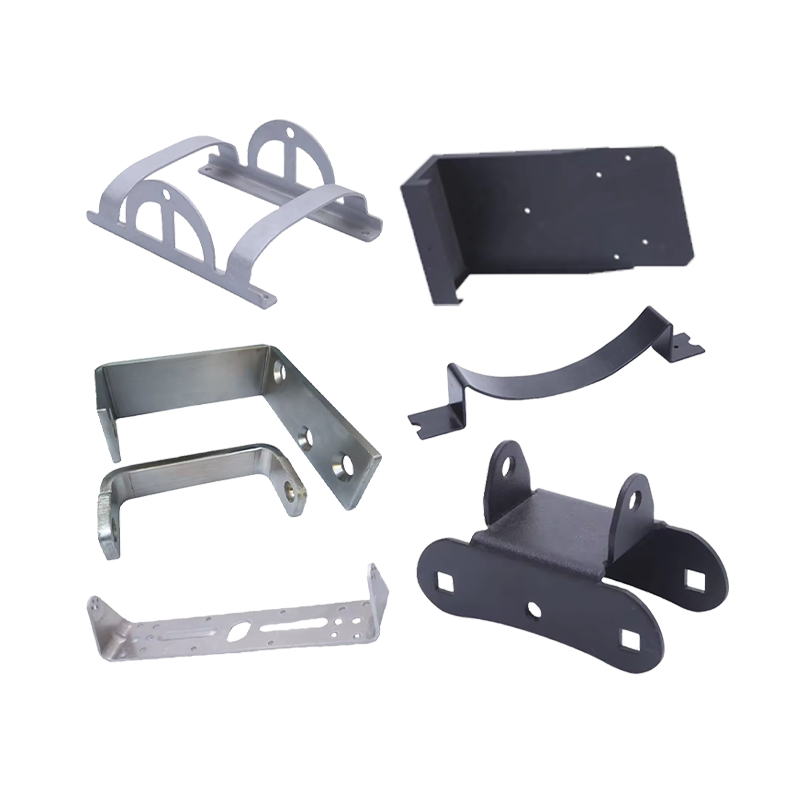

The production of High Precision Components Processing Metal Stamping Parts relies on advanced stamping processes. The stamping process applies pressure to the metal sheet through a mold, causing it to plastically deform to obtain parts of the desired shape and size. In this process, the design of the mold, the selection of materials, the accuracy of the stamping equipment and the control of process parameters are all crucial.

In order to achieve high precision, the stamping process requires strict control of the manufacturing accuracy and wear of the mold to ensure consistent size and shape every time. At the same time, the use of advanced stamping equipment and automated production lines can greatly improve production efficiency and product quality. In addition, for complex-shaped and difficult stamping parts, advanced mold technologies such as multi-station progressive dies and composite dies need to be used to meet production needs.

Different metal materials have a significant impact on the performance of High Precision Components Processing Metal Stamping Parts. Commonly used materials such as stainless steel, aluminum alloy, and titanium alloy have their own advantages in strength, corrosion resistance, and processability.

Stainless steel is widely used in medical, chemical and other fields due to its high strength and good corrosion resistance. Its stable chemical properties and corrosion resistance allow stainless steel stamping parts to maintain good performance in harsh environments. However, the processability of stainless steel is relatively poor, requiring large stamping force and precise process control.

Aluminum alloys are favored in aerospace, automotive and other fields because of their good processability and light weight. Aluminum alloy stamping parts are easy to form and relatively low-cost, but their corrosion resistance is relatively weak, and appropriate surface treatment measures are required to increase their service life.

As a high-end material, titanium alloy occupies an important position in medical implants, aerospace and other fields with its extremely high strength, good corrosion resistance and good biocompatibility. However, titanium alloys are difficult to process, require high equipment and molds, and have relatively high production costs.

High Precision Components Processing Metal Stamping Parts have an extremely wide range of applications, covering almost all manufacturing fields that require precision machining. In the field of medical devices, High Precision Components Processing Metal Stamping Parts are used to manufacture key components such as surgical instruments and implants, which require extremely high biocompatibility and precision. In the aerospace field, titanium alloy stamping parts are widely used in key locations such as engine parts and structural parts due to their good performance. In addition, in the fields of automobiles, electronics, communications and other fields, high-precision stamping parts also play an important role.

With the continuous development and technological advancement of the manufacturing industry, the application fields of High Precision Components Processing Metal Stamping Parts will continue to expand. Especially in emerging fields such as smart manufacturing and new energy vehicles, the demand for High Precision Components Processing Metal Stamping Parts will continue to grow.

What is the specific working principle of the intelligent automatic float system in the drinking bowl?

How does Zinc Coated Steel Deep Drawing Stamping Housing Parts play a good role under different conditions?

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español