Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

Why is Custom Deep Drawing the Secret to High-Performance Metal Components?

Jan 22,2026 -

Why is Deep Drawing the Go-To Solution for Complex Metal Covers?

Jan 15,2026 -

Everything You Need to Know About High-Precision Deep Drawing: Your Ultimate Guide

Jan 08,2026 -

Are stainless steel RV sinks easy to clean?

Jan 01,2026 -

Why are metal animal drinking bowls the best choice for safe pet drinking water?

Dec 23,2025

What is the specific working principle of the intelligent automatic float system in the drinking bowl?

The core of this drinking bowl for cattle and sheep lies in its built-in intelligent automatic float system, which cleverly combines the principles of physics with modern technology to achieve automatic adjustment and precise control of the water level. In short, its working principle is to sense the change of water level through the up and down floating of the float, and trigger the water inlet or water cut-off mechanism accordingly, so as to ensure that the amount of water in the drinking bowl is always kept within the appropriate range.

When cattle and sheep approach the drinking bowl to drink water, the water level gradually decreases as the amount of water decreases. At this time, the float loses some buoyancy and begins to drop with the water level. The downward movement of the float is transmitted to the water inlet valve through a series of precise mechanical structures, triggering the water inlet mechanism. Subsequently, the water source is automatically introduced into the drinking bowl until the water level returns to the preset height. In this process, the float always maintains a floating state synchronized with the water level, ensuring the precise control of the water inlet.

When the water level reaches the preset upper limit, the float floats completely and touches the limit device of the water inlet valve. At this time, the water inlet valve is closed under the push of the float, cutting off the continued inflow of water. At the same time, due to the buoyancy of the float, the valve can be kept in a stable closed state even when the water flow fluctuates or the cattle and sheep are active, effectively preventing the waste of water resources and the overflow of the drinking bowl.

The subtlety of this intelligent automatic float system lies in its high degree of automation and intelligence. It can realize automatic adjustment and precise control of water level without human intervention, greatly reducing the labor intensity and workload of farmers. At the same time, the system also has extremely high reliability and stability, and can maintain normal operation in various harsh breeding environments, providing continuous and stable drinking water guarantees for livestock such as cattle and sheep.

From the perspective of water conservation and environmental protection, the intelligent automatic float system has shown its unique advantages. Traditional drinking water methods are often difficult to accurately control the amount of water, which is easy to cause waste of water resources. The intelligent automatic float system can dynamically adjust according to the actual drinking water needs of cattle and sheep to ensure that every drop of water can be fully utilized. This concept of on-demand water supply not only reflects the respect and cherishment of natural resources, but also sets an example for the green and sustainable development of animal husbandry.

It is commendable that the intelligent automatic float system has good cleanliness and hygiene. The stainless steel material it uses has a smooth surface and is easy to clean, and is not easy to breed bacteria and dirt, ensuring the cleanliness of drinking water. At the same time, the independent operation of the float system also avoids pollutants that may be introduced due to improper human operation, providing a safer and healthier drinking water environment for cattle and sheep.

What are the effects of deep drawing on the coating quality of powder-coated steel parts?

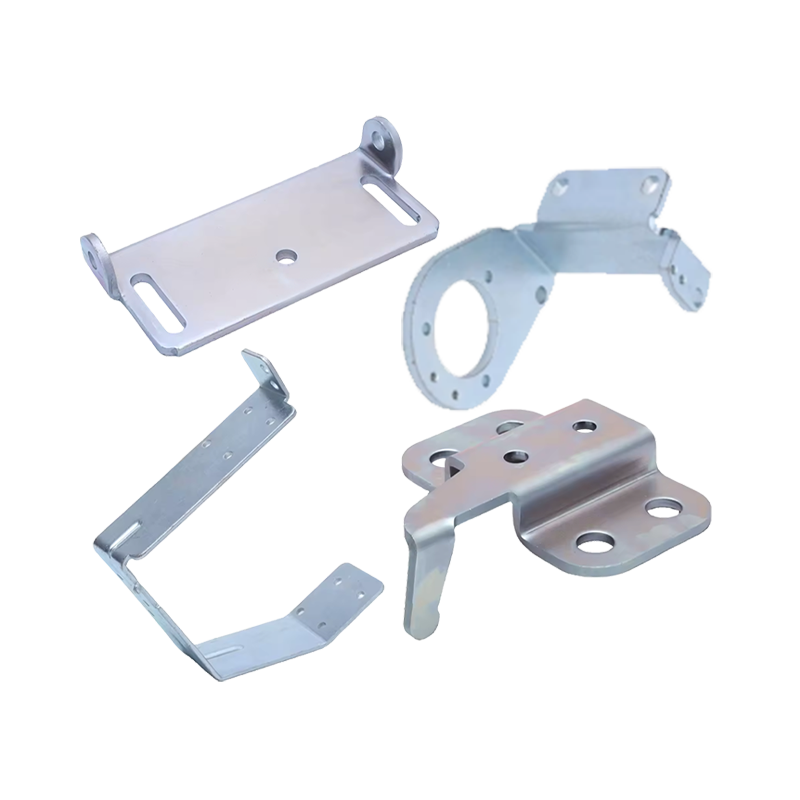

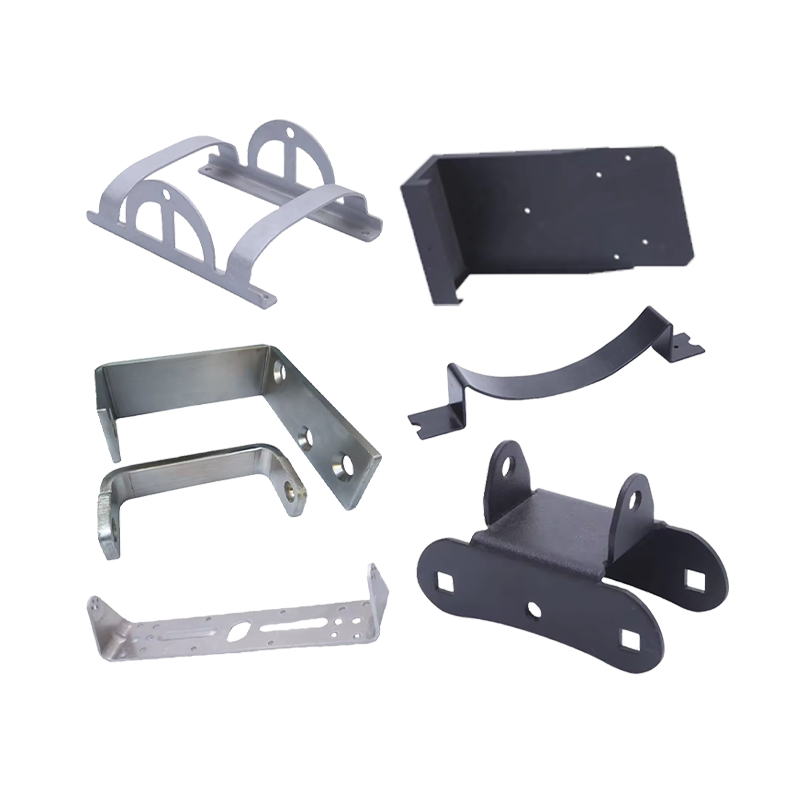

High Precision Components Processing Metal Stamping Parts How to balance the needs of process accuracy, material performance and wide application?

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español