Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

What are the common defects and solutions for metal bending parts?

Dec 16,2025 -

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025 -

Precision Deep Drawing & Metal Stamping Solutions | High-Volume Manufacturing Expertise

Dec 01,2025 -

Which Round Stainless Steel RV Small Cooker Sink With Glass Saves Space? Exploring Space-Efficient Solutions for Mobile Living

Nov 28,2025

How the Size and Design of Pallet Feet Affect the Stability and Safety of Pallets?

Content

Pallets are crucial components in modern logistics and warehousing, and their effectiveness depends not only on the material and structure of the pallet itself but also on the design and size of the pallet feet. Pallet feet are the four supporting structures beneath the pallet that allow it to be lifted, transported, and stored. The size and design of these feet play a significant role in ensuring the pallet's stability, safety, and overall performance. This article explores how the dimensions and design of pallet feet impact pallet stability and safety.

1. The Role of Pallet Feet in Stability

The primary function of pallet feet is to provide a stable base for the pallet. The correct design and size of the feet contribute to how evenly the weight is distributed across the pallet, which is critical when the pallet is stacked or transported.

-

Weight Distribution: Pallet feet help evenly distribute the weight of the pallet and its contents. Larger or more robust feet can handle heavier loads and prevent the pallet from becoming unstable. Uneven weight distribution can lead to tilting or even tipping during stacking, which increases the risk of product damage or injury during handling.

-

Foot Size: The size of the pallet feet is directly related to the surface area they cover. Larger feet provide a wider base of support, enhancing stability by lowering the center of gravity of the pallet. This is especially important when pallets are stacked on top of one another. Pallets with larger feet are less likely to shift or collapse under pressure, contributing to safer stacking and transportation.

-

Foot Placement: The positioning of the pallet feet is just as crucial as their size. Feet that are placed too close together or too far apart can cause the pallet to wobble or become unstable. Properly positioned feet ensure the pallet maintains a balanced center of gravity, preventing excessive swaying or tipping.

2. Safety Considerations for Pallet Feet Design

Safety is a paramount concern in any logistics operation. The design of pallet feet influences how well the pallet can withstand forces such as stacking, impact during transportation, and handling with forklifts.

-

Shock Absorption: Pallet feet with a well-designed profile can absorb shocks and impacts during handling. If the feet are designed with a slightly flexible or cushioned material, they can help absorb impacts, reducing the risk of cracking or breaking the pallet when dropped or bumped. This is especially important in environments where pallets are frequently moved or dropped.

-

Anti-Slip Features: Some pallet feet are designed with anti-slip features, such as textured surfaces or rubberized pads, to increase friction between the pallet and the floor. This helps to prevent the pallet from slipping or shifting when stacked or moved, reducing the risk of accidents. Anti-slip feet are particularly useful in warehouses with smooth floors or during transport on vehicles.

-

Edge Protection: Some pallet feet designs include edge protection or raised edges that prevent the pallet from slipping off shelves or racks. These designs provide extra security, ensuring that pallets remain securely in place even in high-stack environments or during sudden movements.

3. Impact of Pallet Foot Material on Safety and Stability

The material used to make pallet feet also significantly impacts both the stability and safety of the pallet.

-

Plastic Feet: Lightweight and resistant to corrosion, plastic pallet feet are common in food and pharmaceutical industries where hygiene is a priority. However, they may not be as durable under heavy loads or extreme conditions. A thicker, reinforced plastic foot can enhance both stability and safety.

-

Metal Feet: Metal pallet feet, typically made of steel or aluminum, are much more durable and can support heavier loads. They are often used for industrial or heavy-duty applications. Metal feet provide excellent stability and resistance to wear, but they can be prone to rust or corrosion unless properly coated, making it crucial to select the right type of metal for the environment.

-

Rubber Feet: Rubber pallet feet are frequently used for their shock-absorbing qualities. Rubber feet help prevent damage to delicate floors and reduce noise levels during movement. They also provide better grip, improving stability and preventing slipping during transport.

4. Influence on Stackability and Storage Efficiency

The design and size of pallet feet directly affect how pallets stack and how space-efficient the storage system is.

-

Stacking Height: Pallet feet that are designed to interlock or fit precisely into one another allow pallets to be stacked more securely, preventing misalignment. This design can help maximize storage space in warehouses, ensuring that pallets can be stacked higher without the risk of collapse.

-

Space Optimization: The correct size and design of pallet feet also impact the efficient use of space in storage areas. Larger feet may take up more space but can provide greater stability. Smaller feet may reduce the footprint of the pallet, allowing for more compact storage, but the trade-off may be a reduction in stability.

How do Metal Pallet Feet distribute force when loaded to avoid deformation or damage to the pallet?

What space and functional constraints need to be considered when designing an RV sink?

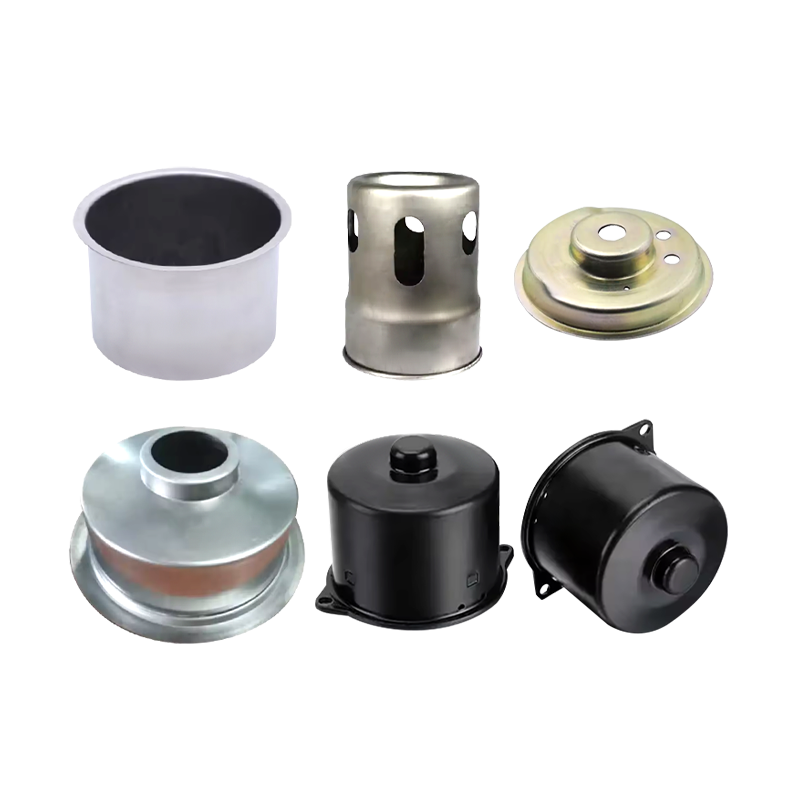

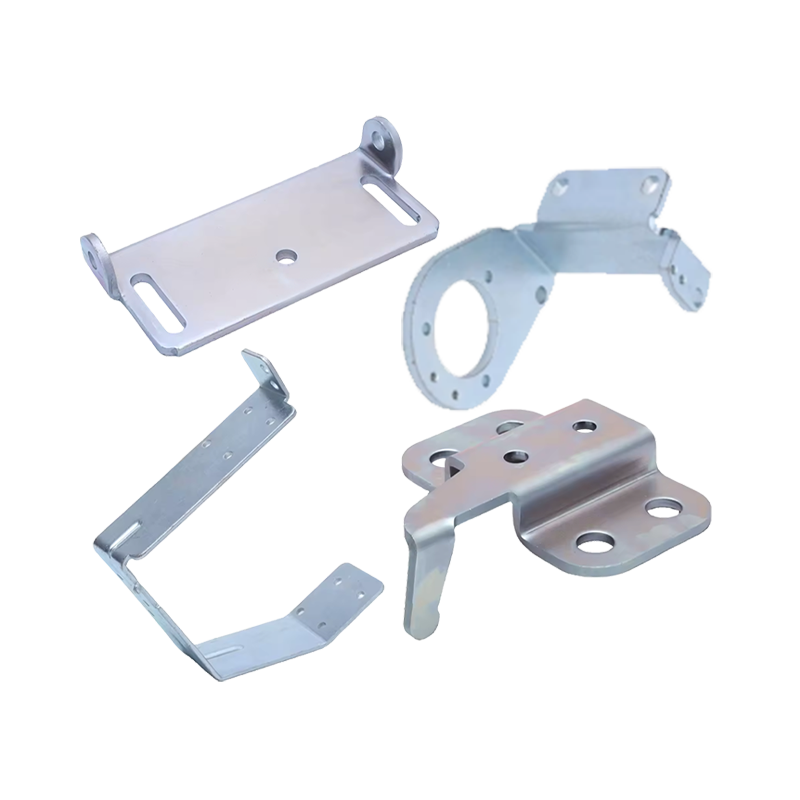

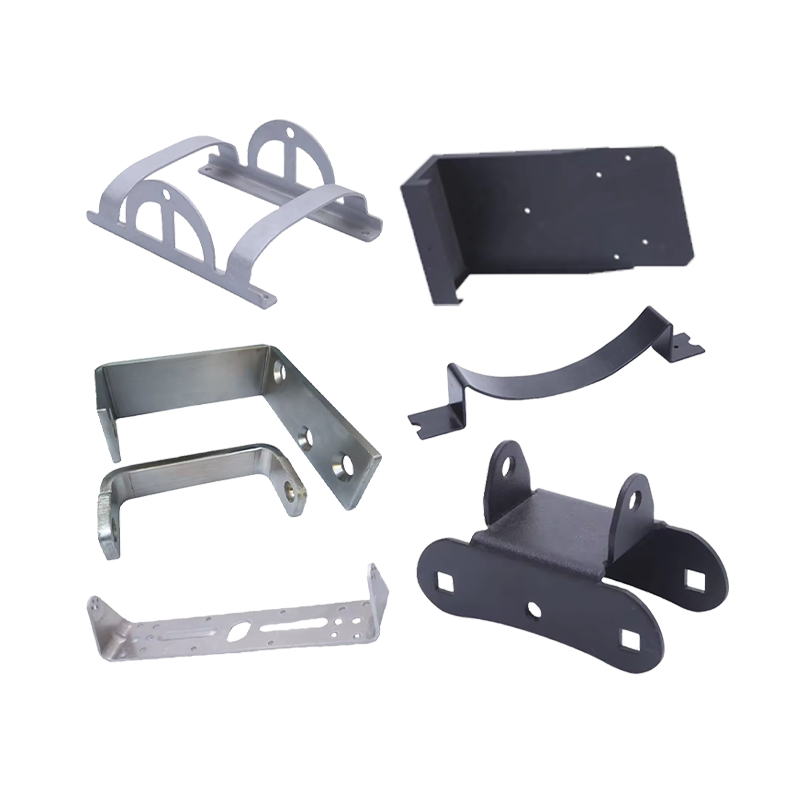

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español