Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

Are stainless steel RV sinks easy to clean?

Jan 01,2026 -

Why are metal animal drinking bowls the best choice for safe pet drinking water?

Dec 23,2025 -

What are the common defects and solutions for metal bending parts?

Dec 16,2025 -

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025

How do Metal Pallet Feet distribute force when loaded to avoid deformation or damage to the pallet?

Metal Pallet Feet is an important part of the pallet. It not only helps to improve the stability of the pallet, but also effectively distributes the load to prevent the pallet from deformation or damage during transportation, stacking and storage. The design and function of the pallet feet are particularly critical when bearing heavy loads. This article will explore how metal pallet feet distribute force when loaded to ensure the structural stability of the pallet and avoid damage caused by uneven load.

Basic principles of load distribution

One of the main functions of metal pallet feet is to evenly distribute the load to the ground or the contact point at the bottom of the pallet by carrying the weight of the pallet. The pallet feet not only need to bear the weight in the vertical direction, but also need to ensure that the load is evenly transferred to other parts of the pallet to prevent local excessive force from causing deformation or damage. Therefore, the design of the pallet feet needs to take into account the distribution of the load to avoid excessive pressure on a single part.

In order to distribute the load, the design of metal pallet feet usually adopts the following methods:

Evenly distribute the load: Metal pallet feet are usually set at the four corners of the pallet, or more support points are added on larger pallets. This design makes the weight on each pallet foot more uniform, avoids excessive local force, and ensures that the load of the entire pallet is evenly distributed.

Design of support points: The design of the support surface of the pallet foot directly affects the distribution of the load. Usually, the bottom of the metal pallet foot is designed to have a larger contact surface, which helps to spread the load to a wider area, thereby reducing local pressure. A larger support surface helps to reduce the generation of indentations and avoid tilting caused by uneven ground.

Foot shape and structural optimization: Modern metal pallet feet are optimized in shape and structure, such as using more elastic materials or structurally reinforced feet to disperse pressure and reduce the impact on the pallet body. By designing metal pallet feet with a certain degree of elasticity, some impact forces can be effectively absorbed to avoid damage to the pallet itself due to excessive external pressure.

Material selection of pallet feet

The material of the metal pallet foot directly affects its force distribution ability when loaded. Common materials include steel, aluminum alloy and stainless steel. Each material has different rigidity and elasticity, and its performance in load distribution is also different.

Steel: Steel is one of the most commonly used materials for metal pallet feet. It can effectively support pallets under high loads due to its high strength and load-bearing capacity. Steel pallet feet are usually strong, but their disadvantage is that they lack elasticity and are easily deformed due to overload. Therefore, when designing steel pallet feet, it is necessary to consider enhancing their load-bearing capacity and avoiding excessive local stress.

Aluminum alloy: Aluminum alloy is lighter than steel and has better corrosion resistance. Although its strength is lower than that of steel, aluminum alloy pallet feet are usually designed with a larger contact surface, thereby compensating for the lack of material strength by increasing the support area. Aluminum alloy has strong elasticity and can better disperse load pressure, but its deformation ability is strong under heavy loads, and extra attention needs to be paid to the thickness and strength design of the material.

Stainless steel: Stainless steel has strong corrosion resistance and durability, and is suitable for metal pallet feet in harsh environments. In terms of load distribution, stainless steel is similar to steel, but it is more durable and suitable for long-term high-load use. However, due to the higher cost of stainless steel, pallet feet of this material are often used in high-end markets or special applications.

Impact of load distribution on pallet structure

In the process of pallet load distribution, metal pallet feet play a vital role in the structural stability of the pallet. If the load is uneven, a part of the pallet foot may be subjected to excessive pressure, causing deformation of the area, and even damage to the entire pallet. Therefore, the reasonable design of the number, position and load-bearing capacity of the metal pallet feet is the key to ensure the long-term stable use of the pallet under load.

Load distribution during stacking: Pallets often need to be stacked during storage and transportation. At this time, the weight of the stacked pallets will be transferred to the ground or other pallets through the pallet feet below. The design of the metal pallet feet needs to ensure that the weight of the upper pallet can be evenly distributed to the feet of the lower pallet to avoid deformation of the lower pallet due to excessive pressure.

Support capacity of pallet feet: Pallet feet not only need to support the load, but also need to avoid instability caused by external impact or uneven ground. For example, during transportation, the pallet feet may contact uneven ground. If the pallet feet are not designed properly, it may cause the pallet to tilt or overturn. Reasonable support design can prevent this from happening.

Weight distribution and stress analysis: For different types of pallets, the load is distributed in different ways. Through stress analysis of pallet feet, designers can better determine the support point location and strength of metal pallet feet to ensure stable and reliable performance in various working environments.

How to Choose the Right Metal Pallet Feet Based on Usage Scenarios?

How the Size and Design of Pallet Feet Affect the Stability and Safety of Pallets?

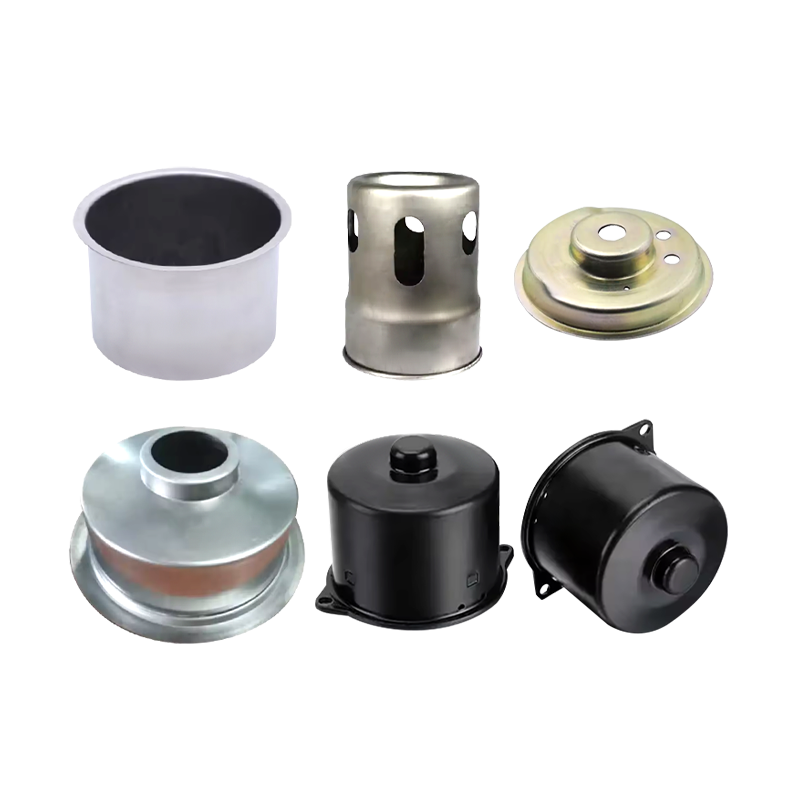

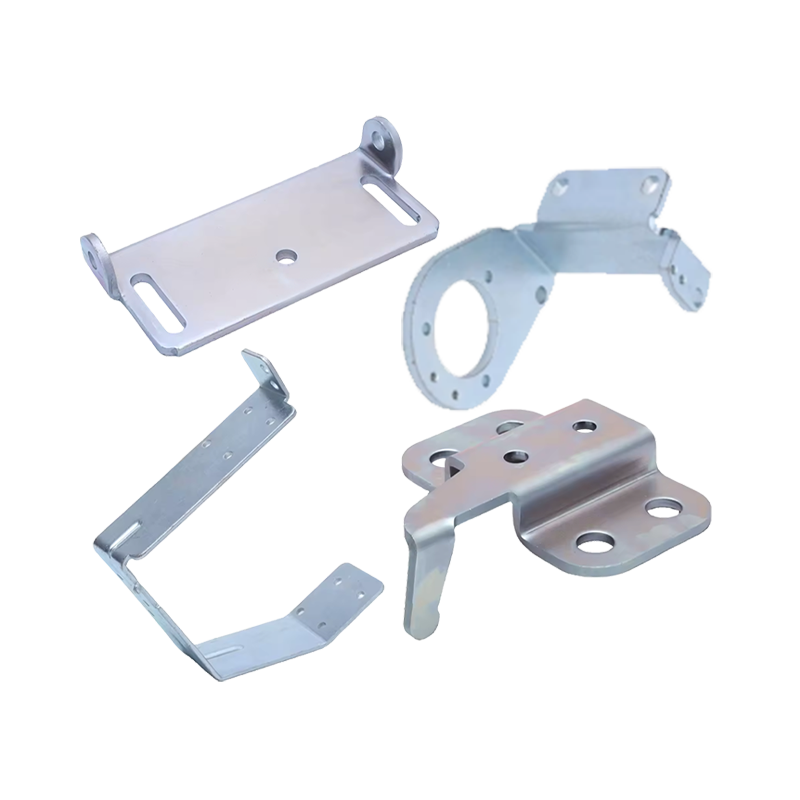

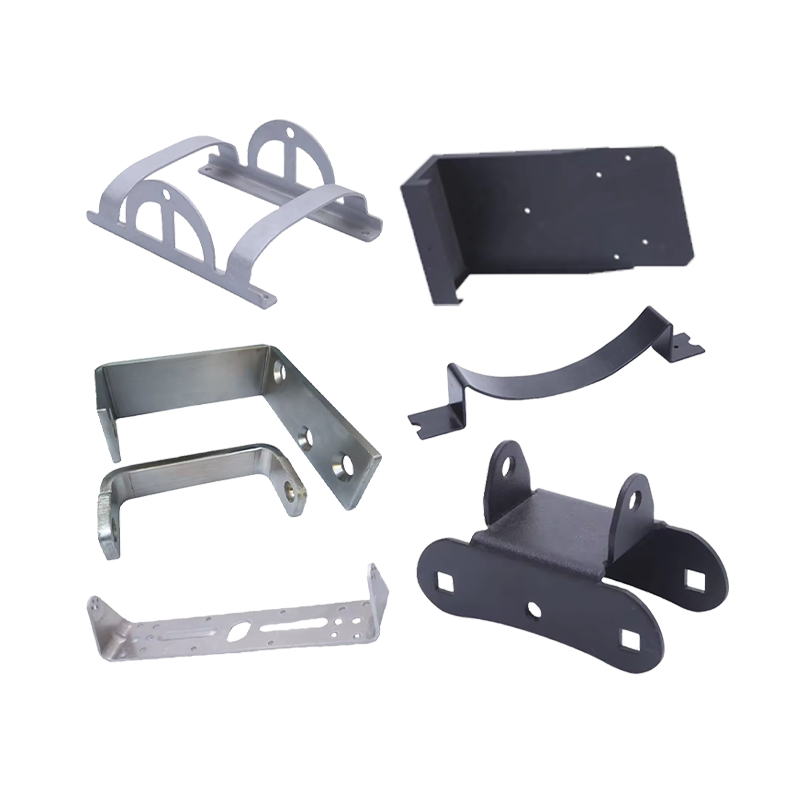

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español