Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

Why are metal animal drinking bowls the best choice for safe pet drinking water?

Dec 23,2025 -

What are the common defects and solutions for metal bending parts?

Dec 16,2025 -

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025 -

Precision Deep Drawing & Metal Stamping Solutions | High-Volume Manufacturing Expertise

Dec 01,2025

How to Choose the Right Metal Pallet Feet Based on Usage Scenarios?

Content

Metal pallet feet are essential components in pallet design, significantly enhancing the stability, durability, and versatility of pallets in various storage and transportation applications. Choosing the right metal pallet feet can not only improve the performance of the pallet but also extend its service life.

Understanding the Requirements of the Usage Scenario

The first step in selecting the right metal pallet feet is to understand the specific usage scenario of the pallet. This includes factors such as the type of load the pallet will carry, the environment in which it will be used, the storage method, and transportation conditions. Different scenarios have different functional demands for pallet feet, so selecting the appropriate ones is crucial for achieving the best performance.

Load Type and Weight

One of the primary functions of pallet feet is to bear the weight and load of the pallet. When choosing metal pallet feet, it's important to select those that can handle the weight of the goods being transported or stored. For pallets that carry heavy loads, metal feet made from materials such as steel or reinforced metal are ideal, as they offer higher load-bearing capacity. For lighter pallets, smaller, lighter metal feet may be sufficient.

Usage Environment

The environment in which the pallet will be used plays a significant role in selecting metal pallet feet. Different environmental conditions require different materials and designs. For example, in high-temperature environments, the metal feet need to be made from heat-resistant materials. In humid or corrosive environments, corrosion-resistant feet are essential. For clean or sterile environments, smooth and easy-to-clean metal feet may be preferred.

Storage and Transportation Methods

The way pallets are stored (stacked, tiered, or horizontally placed) also affects the choice of metal pallet feet. In stacking scenarios, the feet must be able to provide stability to prevent the pallet from toppling or becoming deformed. When transporting pallets, the design of the feet should account for movement, sliding, or exposure to external forces. Therefore, the frictional properties and stability of the pallet feet need to be carefully considered.

Key Factors in Selecting Metal Pallet Feet

When choosing metal pallet feet based on usage scenarios, several key factors need to be carefully considered.

Material Selection

The material of the pallet feet directly influences their load-bearing capacity, durability, and adaptability. Common materials used for metal pallet feet include:

Steel: Steel pallet feet are strong and durable, making them ideal for heavy-duty pallets that need to withstand high loads. Steel feet also provide excellent compression resistance and are suitable for logistics and warehouse environments.

Aluminum: Aluminum pallet feet are lightweight and have good corrosion resistance, making them suitable for light-duty pallets or environments where corrosion is a concern, such as the food or chemical industries.

Stainless Steel: Stainless steel pallet feet offer superior corrosion resistance and strength, making them ideal for harsh environments such as chemical storage, cold-chain logistics, or high-humidity settings.

Galvanized Steel: Galvanized steel feet are coated with a layer of zinc to resist rust, making them suitable for environments that are damp or mildly corrosive, ensuring longer service life.

Load-Bearing Capacity and Stability

The feet must be able to handle the weight of the pallet and maintain stability. Heavier loads require metal feet that are designed for higher load-bearing capacity. Reinforced or larger feet may be needed for heavy-duty applications. Additionally, the design and structure of the feet must ensure even distribution of weight to prevent local pressure points that could lead to deformation or damage.

Corrosion Resistance and Wear Resistance

In humid or corrosive environments, choosing metal pallet feet with strong corrosion resistance is crucial. Materials like aluminum, stainless steel, and galvanized steel are particularly well-suited for environments that involve moisture or chemicals, ensuring that the pallet feet will remain functional for a longer period. The surface treatment of the pallet feet, such as powder coating or galvanization, also plays a role in increasing their wear resistance and longevity.

Adjustable Functionality

Some metal pallet feet are designed with adjustable features that allow users to modify the height of the pallet. This is especially important when pallets are used on uneven surfaces. Adjustable feet help maintain stability by ensuring that the pallet remains level, preventing tilting or instability during storage or transportation. For precise adjustments, such as in environments where precise stacking is required, adjustable metal pallet feet are an ideal choice.

Anti-Slip Design

Anti-slip features in metal pallet feet are important, especially when the pallet needs to slide across smooth or slippery surfaces. Anti-slip designs can be achieved through the addition of rubber pads, grooves, or textured surfaces. These features increase friction between the feet and the floor, reducing the risk of the pallet sliding or moving unexpectedly, which helps to ensure greater stability during transportation or storage.

Special Usage Scenarios and Foot Selection

High-Temperature Environments

In high-temperature environments, the metal pallet feet should be made of heat-resistant materials such as aluminum alloys or heat-resistant stainless steel. These materials can withstand prolonged exposure to high temperatures without warping, weakening, or failing, making them ideal for industries such as automotive manufacturing or steel production.

Cold-Chain Logistics

For cold-chain logistics, pallet feet need to be able to withstand freezing temperatures and maintain their structural integrity. Materials like stainless steel and aluminum alloys are suitable for cold environments, as they not only resist corrosion but also have low susceptibility to brittleness at low temperatures.

Hygienic and Clean Environments

In industries like food processing, pharmaceuticals, and healthcare, where hygiene is a top priority, the metal pallet feet should be smooth, easy to clean, and resistant to bacterial growth. Stainless steel and aluminum are often preferred due to their smooth surfaces, which can be easily sanitized. Additionally, these materials are resistant to contamination, ensuring that the pallets remain safe for sensitive products.

Surface Treatment Methods for Metal Pallet Feet and How to Prevent Corrosion?

How do Metal Pallet Feet distribute force when loaded to avoid deformation or damage to the pallet?

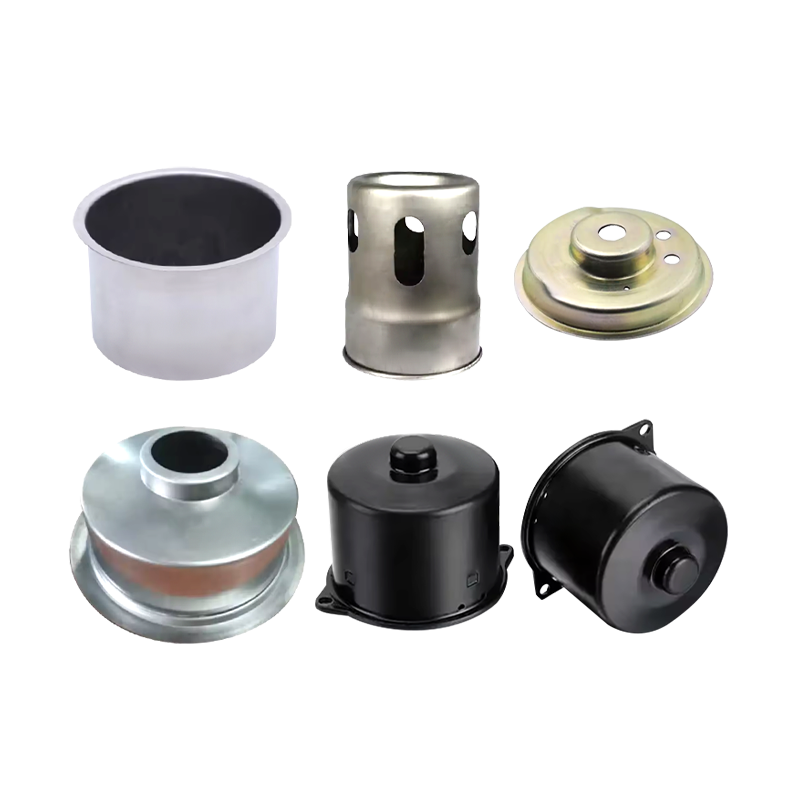

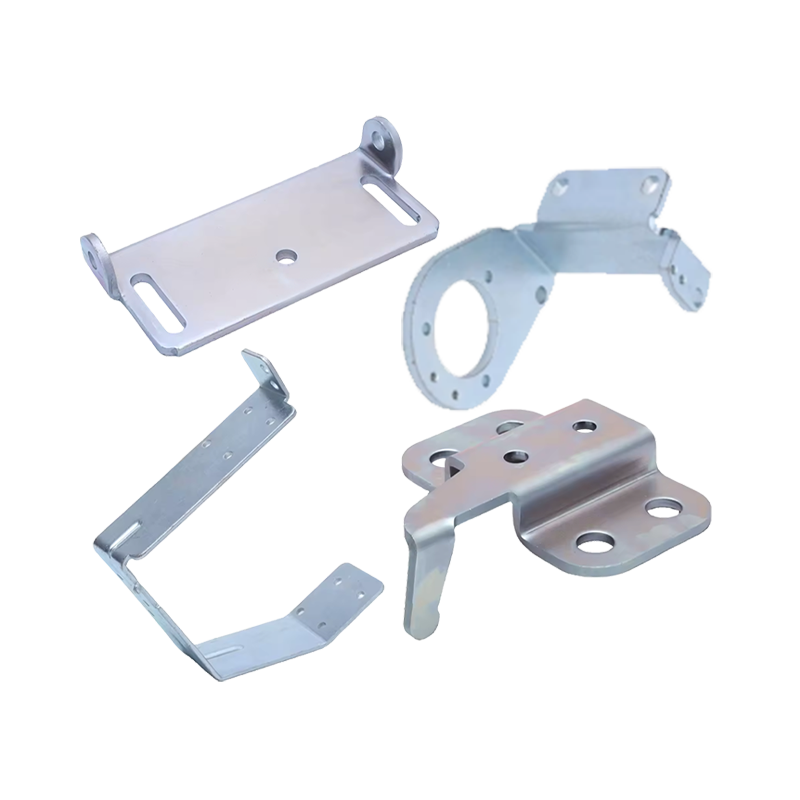

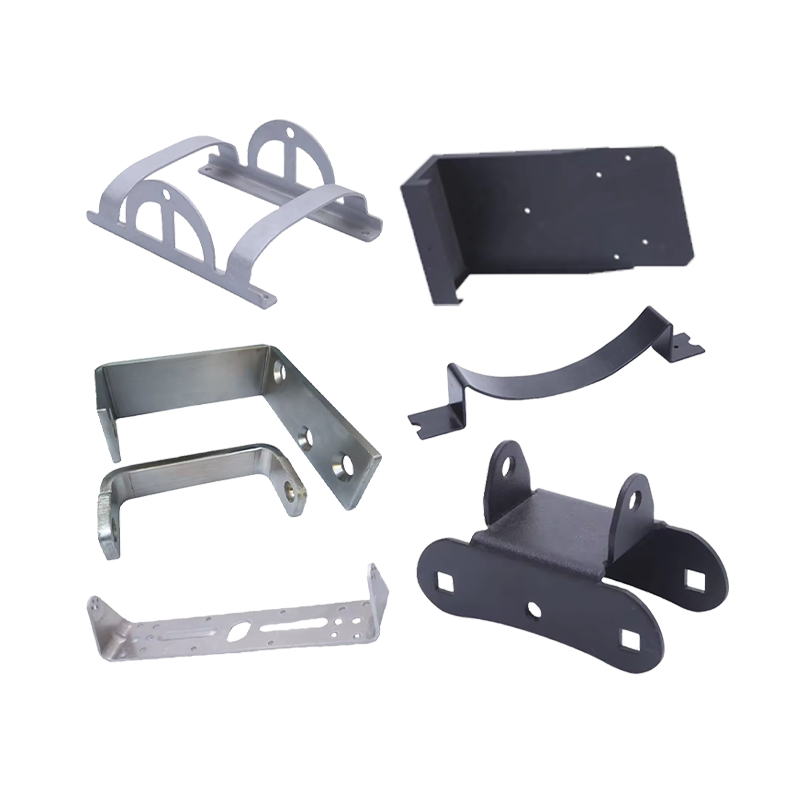

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español