Web Menu

Product Search

Exit Menu

News categories

RECENT POSTS

-

Why are metal animal drinking bowls the best choice for safe pet drinking water?

Dec 23,2025 -

What are the common defects and solutions for metal bending parts?

Dec 16,2025 -

What to do if burrs appear on metal stamping parts? How to avoid them?

Dec 09,2025 -

What are Metal Bending and Drawing Parts?

Dec 02,2025 -

Precision Deep Drawing & Metal Stamping Solutions | High-Volume Manufacturing Expertise

Dec 01,2025

Surface Treatment Methods for Metal Pallet Feet and How to Prevent Corrosion?

Metal pallet feet are an essential component in ensuring the stability and durability of pallets, especially in industrial and logistics applications. Since these feet are subjected to varying environmental conditions, it is crucial to protect them from damage and corrosion. The surface treatment of metal pallet feet plays a significant role in enhancing their performance and longevity. There are several surface treatment methods available to prevent corrosion, each suited for specific environmental requirements.

One of the most common methods for treating metal pallet feet is galvanization. This process involves coating the metal with a layer of zinc, which acts as a protective barrier. The zinc coating forms a sacrificial layer, meaning it corrodes first, protecting the underlying metal from rust and degradation. Galvanized metal pallet feet are particularly suited for outdoor and humid environments, where exposure to water and moisture could otherwise lead to rapid corrosion. Hot-dip galvanization is the most widely used form, where the metal is dipped into a bath of molten zinc to ensure a strong and durable coating.

Another effective method is powder coating, which involves applying a dry powder to the surface of the metal and then curing it under heat. The powder coating creates a tough, protective layer that is resistant to chipping, scratching, and fading. This method not only provides excellent corrosion resistance but also enhances the appearance of the pallet feet, as the coating can be applied in a wide range of colors. Powder-coated metal pallet feet are ideal for indoor use, as well as for applications where aesthetics and durability are equally important.

Anodizing is a surface treatment primarily used for aluminum metal pallet feet. This electrochemical process thickens the natural oxide layer on the surface of the metal, making it more resistant to corrosion and wear. Anodized metal pallet feet have a matte finish that is both aesthetically pleasing and highly durable. Anodizing is especially useful in environments where the pallet feet are exposed to both harsh chemicals and high wear conditions, as it provides an extra layer of protection.

Electroplating is another method used to improve corrosion resistance. It involves using an electric current to deposit a thin layer of metal, such as chromium or nickel, onto the surface of the pallet feet. Electroplated metal pallet feet are highly resistant to corrosion, especially in environments where chemical exposure is a concern. Chromium plating, in particular, is known for its ability to withstand harsh environments and provides a glossy finish that is also aesthetically appealing.

Paint coatings are one of the simplest and most cost-effective ways to protect metal pallet feet. High-quality paint, especially epoxy or polyurethane-based paints, forms a strong barrier that helps prevent moisture from reaching the metal surface. Painted metal pallet feet are suitable for environments where exposure to water or chemicals is moderate. However, regular maintenance is required to ensure the coating remains intact, as paint can chip or wear off over time.

To further protect against corrosion, passivation is often used, particularly in stainless steel pallet feet. Passivation involves treating the metal with a special acid solution that removes free iron from the surface and enhances the natural oxide layer. This process improves the metal’s resistance to rust and corrosion, particularly in environments with high humidity or exposure to certain chemicals.

For extreme conditions, ceramic coatings are sometimes applied to metal pallet feet. These coatings provide an excellent barrier against corrosion, abrasion, and extreme temperatures. Ceramic-coated pallet feet are typically used in high-performance applications, such as heavy industrial environments or areas where exposure to high heat is common.

The proper surface treatment method for metal pallet feet largely depends on the specific application and environmental conditions. In general, for outdoor or humid environments, hot-dip galvanization and powder coating are often the best options. For indoor applications where aesthetics and durability are both important, powder coating and anodizing can provide excellent results. Additionally, electroplating and passivation are ideal for environments where chemical exposure is prevalent.

Regardless of the surface treatment method, proper maintenance and inspection of metal pallet feet are essential to prolong their service life. Regular cleaning and re-coating, when necessary, can help maintain the integrity of the protective layers and prevent corrosion from taking hold. By selecting the right surface treatment and performing regular maintenance, businesses can significantly extend the lifespan of their metal pallet feet and ensure that they continue to provide reliable support for pallets in any environment.

What types of pallets are metal pallet feet suitable for?

How to Choose the Right Metal Pallet Feet Based on Usage Scenarios?

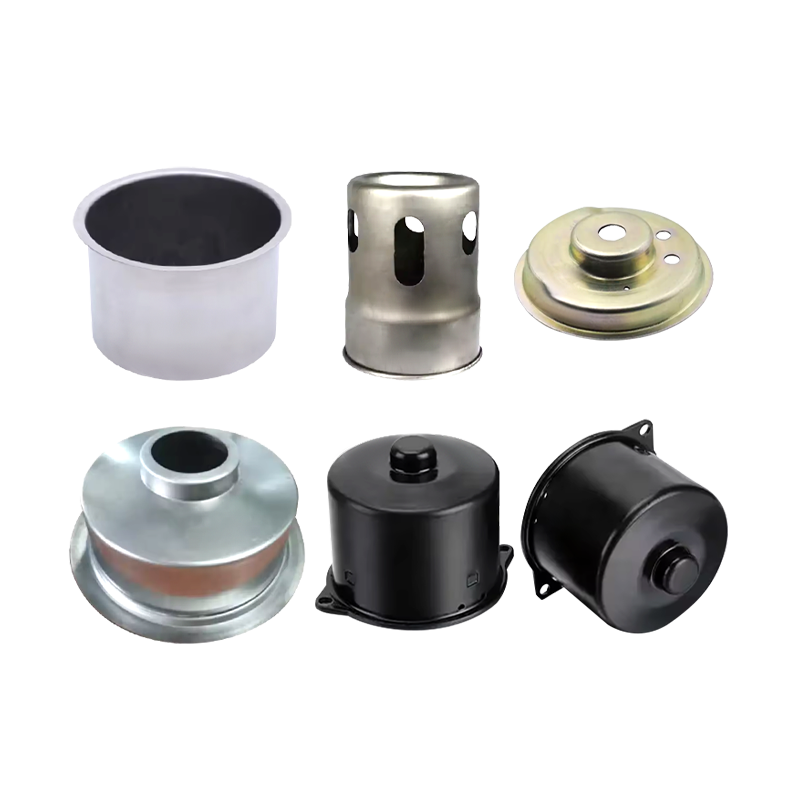

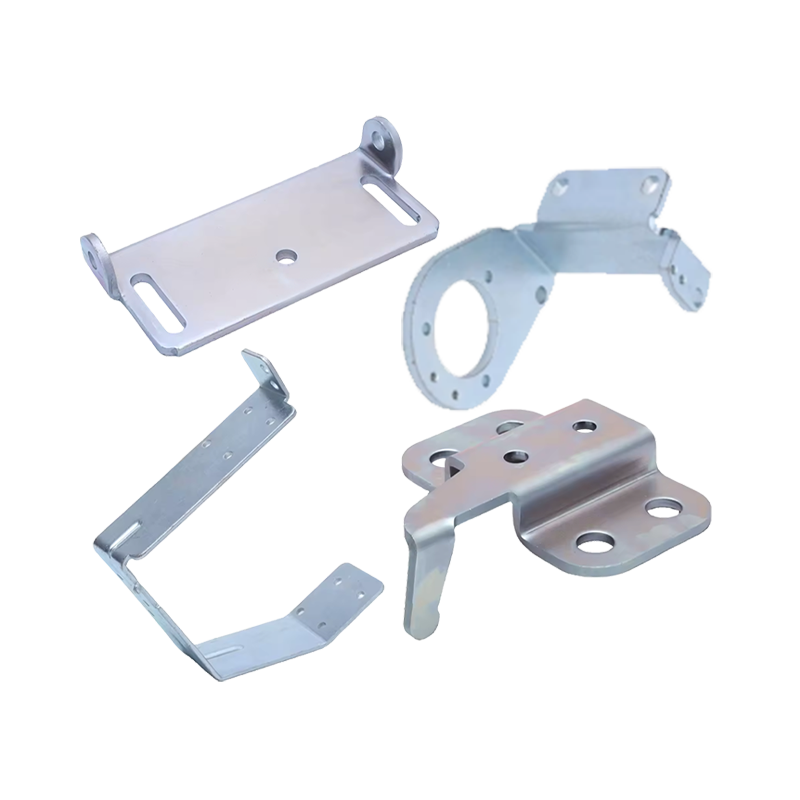

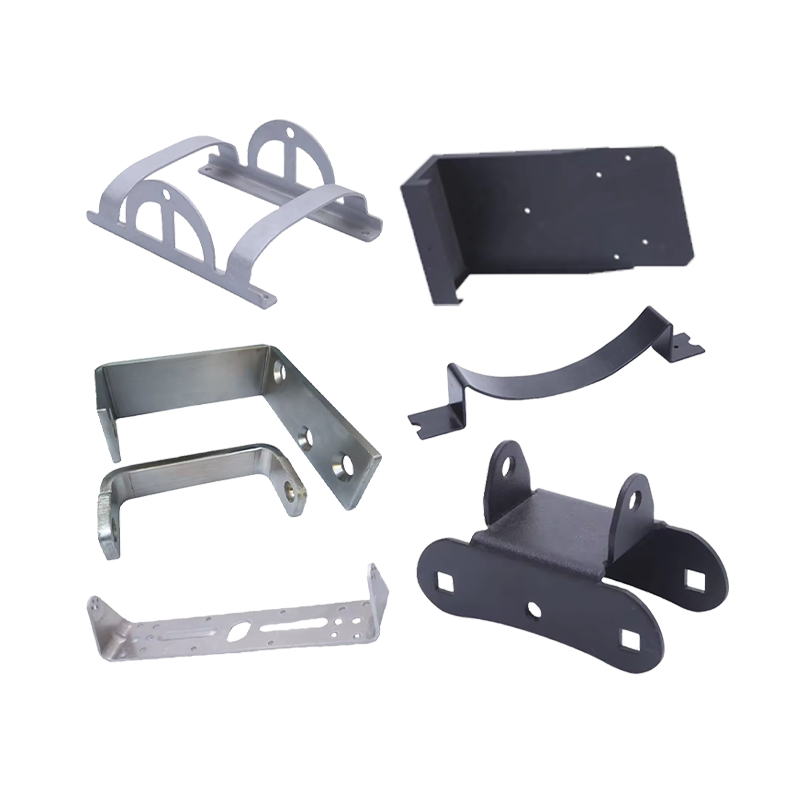

related products

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally

contact UsPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: Unit 2, Building 19, Zhichuangzhizao Park, Chengdong Industrial Zone, Xiangshan, Ningbo,315705, Zhejiang, China

English

English 中文简体

中文简体 Español

Español